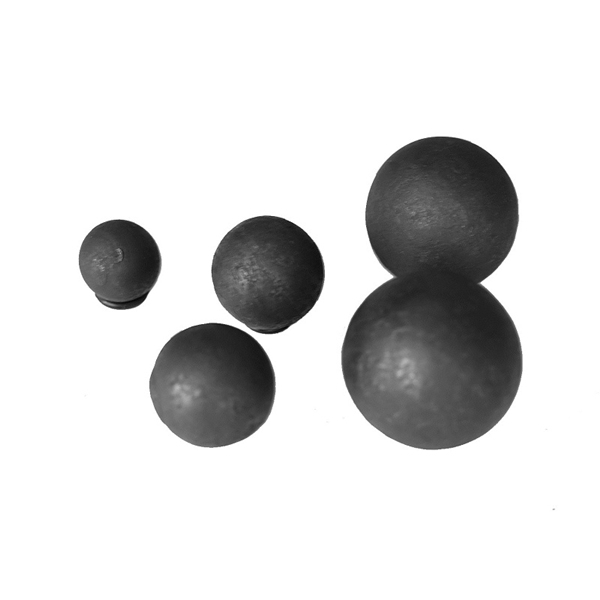

Sag Mill Grinding Ball

Brand ZW

Product origin Shandong, China

Delivery time 7 days

Supply capacity 6000 tons per month

Grinding steel balls are divided into three types: forged steel balls, cast steel balls, and hot-rolled steel balls.

1. Forged Steel Balls

Forged steel ball, with good surface quality, good impact resistance, strong toughness, good wear resistance, not easy to break and out of round. It refers to the processing method of heating the metal to 700-1300 ℃, applying pressure to the metal blank by forging to make it plastic deformation to obtain forgings with certain mechanical properties, shapes and sizes.

Forged steel balls are favored by the majority of users because of their low price, economic durability and other characteristics. For example, international mining giants Rio Tinto, BHP Billiton and Anglo Gold all use forged steel balls.

2. Cast steel ball

Among cast steel balls, chromium alloy is the main component of cast steel balls. Its oxidation resistance and resistance to high sulfur, diesel fuel and seawater corrosion are poor. Its strength density is lower than that of forged steel balls, and its crushing rate is much higher than that of other process steel balls. According to the chromium content, wear balls can be divided into the following categories:

a. Chromium content 1% - 3%, hardness HRC ≥ 45. This standard wear-resistant steel ball is called low chromium alloy cast ball, and low chromium ball is produced by medium frequency electric furnace smelting, metal mold or sand casting. Its performance is applicable to some metallurgical mines, slag and other industries with low grinding precision requirements and low wear consumption.

b. Chromium content 4% - 6%, hardness HRC ≥ 47. This standard is called multi-element alloy ball, which has higher strength and wear resistance than low chromium steel ball.

c. The medium chromium alloy cast ball with chromium content of 7% - 10% and hardness of HRC ≥ 50 is superior to the multi-element alloy steel ball in properties.

d. Chromium content ≥ 10% - 14%, hardness HRC ≥ 58, high chromium alloy cast ball, is a kind of wear-resistant ball with high utilization rate and good wear resistance in the cement industry, which has a wide range of applications. However, due to high price and good performance, it has been replaced by forged products, causing a gradual decline in the market.

e. Chromium content exceeds 14%, hardness HRC ≥ 58. This is a special high chromium steel ball, which is suitable for industries with more meticulous grinding and high consumption. Of course, its price is also quite high, and its cost performance ratio is slightly lower than that of high chromium ball.

3. Hot-rolled steel balls

According to the different raw materials used, the performance of steel balls is different. They can be roughly divided into these types. Take 100mm steel balls as an example.

Surface HRC55-60, core hardness 20-25

Surface hardness 55-60 Heart hardness 30-35

Surface hardness 58-63 Heart hardness 40-45

Surface hardness 58-63, core hardness 55-60

The surface hardness is above 60, and the core hardness is above 58. The hot-rolled steel ball is produced by the rotary cutting production line. Mainly, the fourth and fifth types of super-large enterprises are the main ones, such as China Gold, Jiugang Group, and Tongling Nonferrous Metals.