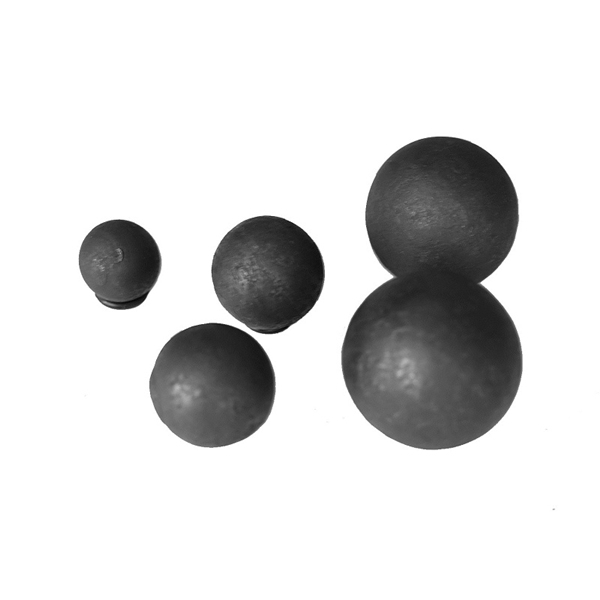

Grinding Media Ball

Brand ZW

Product origin Shandong, China

Delivery time 7 days

Supply capacity 6000 tons per month

The grinding balls produced by Jinan Zhongwei are widely used in gold, silver and copper mines, cement plants, thermal power plants, chemical plants and other fields.

Our factory has a strict quality control system. Each batch will be randomly checked for chemical composition, hardness, drop test, and impact to ensure that every ball received by the customer is qualified.

Download

Wear-resistant steel grinding balls, also known as wear-resistant media for grinding machines, are consumables. The main purpose is to grind materials to make them finer to meet the standard of use. They are mainly used in mines, power plants, cement plants, iron and steel plants, It is used in silica sand factories, coal chemical industry and other fields.

Steel balls are divided into three types: forged steel balls, cast steel balls, and hot-rolled steel balls.

Forged steel ball: It is made of round steel and then forged with an air hammer. The wear resistance of forged steel balls has a lot to do with the material of the round steel used and the quality of impurities or round steel.

In cast steel balls, chromium alloy is the main component of cast steel balls. It has poor oxidation resistance and resistance to high sulfur, diesel fuel, and seawater corrosion. Its strength density is lower than that of forged steel balls, and its crushing rate is much higher than that of other process steel balls. . According to the level of chromium content, wear-resistant balls can be divided into high chrome ball, medium Cr ball and low chrome cast ball.

Compared with forged steel balls, hot-rolled steel balls have higher production efficiency, high degree of automation, and reduce manual operations. They have the characteristics of high overall hardness, dense structure, no loss of roundness, no broken, no deformation and high cost performance.