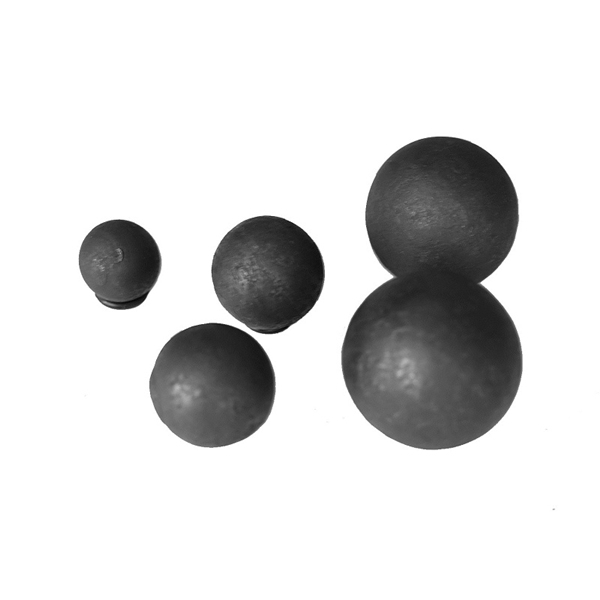

Ball Mill Grinding Ball

Brand ZW

Product origin Shandong, China

Delivery time 7 days

Supply capacity 6000 tons per month

Our factory has a strict quality control system. Each batch will be randomly checked for chemical composition, hardness, drop test, and impact to ensure that every ball received by the customer is qualified.

Download

Forged steel ball, good surface quality, good impact resistance, strong toughness, good wear resistance, not easy to break and out of round. It is a processing method that heats the metal to a temperature of 700-1300 ° C, and applies pressure to the metal blank by forging to make it plastically deform to obtain a forging with certain mechanical properties, certain shape and size. Through forging, defects such as as-cast looseness produced by the metal during the smelting process can be eliminated, and the microstructure can be optimized. At the same time, due to the preservation of the complete metal streamline, the mechanical properties of forgings are generally better than those of castings of the same material. In addition, the most wear-resistant materials must be selected for forging steel balls to be wear-resistant. Because it is the same material, the quality produced in different steel plants is also different, and the quality of forgings is 80% dependent on the quality of the material, such as high manganese steel, which has good impact resistance and strong toughness. , good wear resistance, not easy to break

Forged steel ball production process

Raw material inspection → blanking → intermediate frequency furnace heating → forging (roll forging) into balls → quenching treatment → tempering treatment → testing → packaging

Application field

Various types of metal mines (gold, copper, iron, molybdenum, alumina), cement plants, power plants, steel slag plants, quartz sand plants, etc.