B2 Material Forged Ball

Brand ZW

Product origin Shandong, China

Delivery time 7 days

Supply capacity 6000 tons per month

The grinding balls produced by Jinan Zhongwei are widely used in gold, silver and copper mines, cement plants, thermal power plants, chemical plants and other fields.

Our factory has a strict quality control system. Each batch will be randomly checked for chemical composition, hardness, drop test, and impact to ensure that every ball received by the customer is qualified.

Download

For customers with diameter above 40mm and special requirements, we can provide traditional forged steel balls. Forged steel balls also use our custom-grade raw materials. The operators have an average of more than five years of forging ball manufacturing experience to ensure that the size of the ball is uniform and the surface is smooth; at the same time, each ball is subjected to strict quenching and tempering heat treatment. In the case of ensuring uniform hardness inside and outside, taking into account the toughness, the sphere has good impact resistance, strong toughness, wear-resistant and not easy to break. After inspection, the hardness of the grinding ball surface is as high as HRC58-65, the volume hardness is as high as HRC56-63, the impact toughness is greater than 15j/cm2, the drop test is greater than 10,000 times, and the actual breakage rate is less than 0.5%.

ZW forged grinding ball main materials:

Chemical elements | |||||

C | Si | Mn | P/S | Cr | |

B2 | 0.72-0.85 | 0.17-0.37 | 0.7-1.0 | <0.04 | 0.4-0.6 |

60Mn | 0.55-0.65 | 0.17-0.37 | 0.7-1.0 | <0.04 | <0.25 |

45# | 0.42-0.50 | 0.17-0.37 | 0.5-0.8 | <0.035 | ≤0.25 |

B3 | 0.58-0.66 | 1.6-1.9 | 0.65-0.8 | <0.025 | 0.7-0.9 |

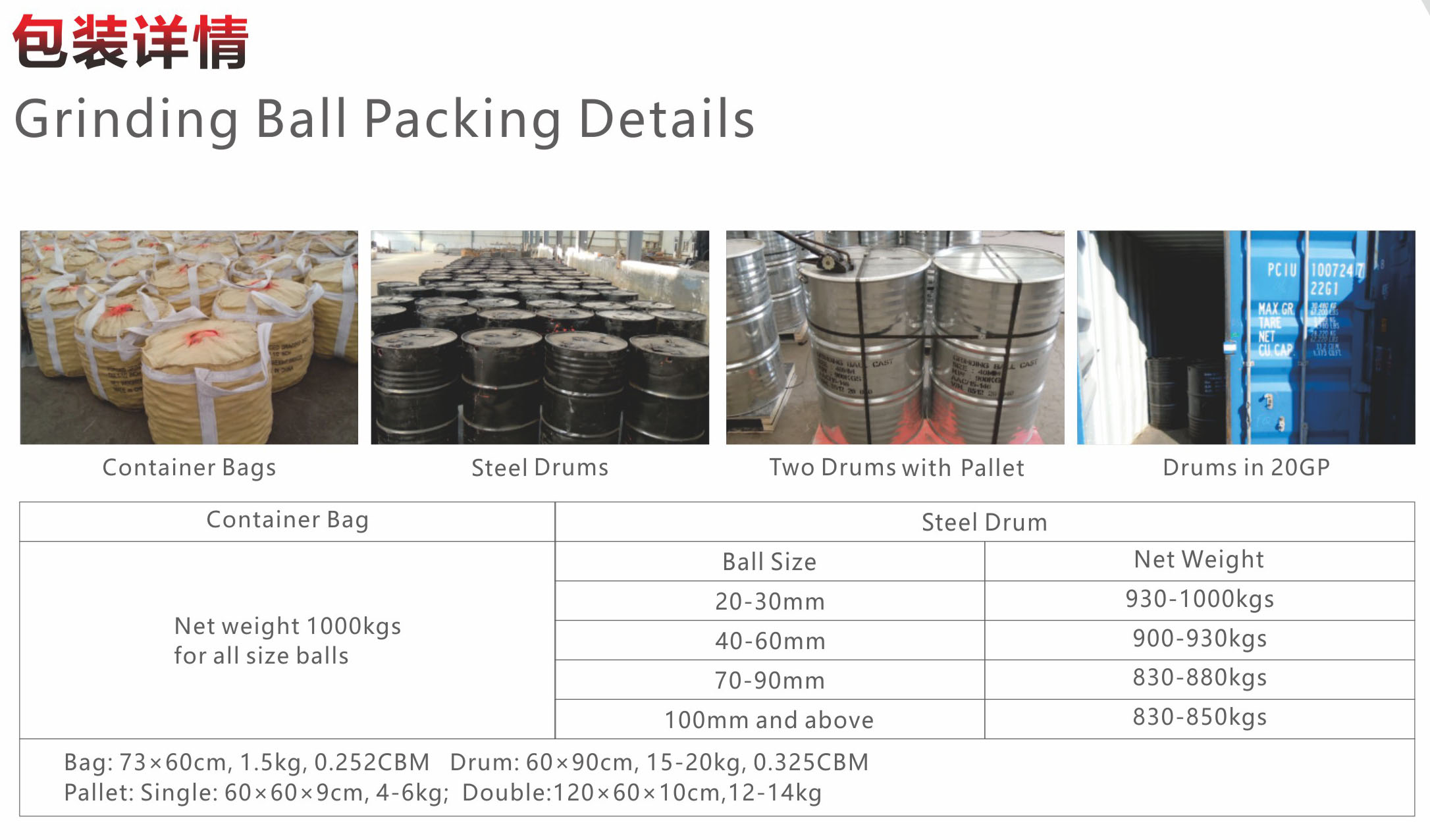

Packing

Steel drum (800-950kg per drum) &Container Bag (1000kg per bag)

QC&QI

1) Raw material: Size, Chemcial elements, Microstructure quality control (LAIWU STEEL)

2) Production Technical: Cutting Size, Heating Temperature, Quenching Technical, Tempering control.

3) Grinding Balls: Hardness, Size, Chemcial elements, Breakage Rate Checking

4) Thrid-Pary: SGS, BV ISO, TUV, COTECNA, AsiaInspection etc.