Medium Chrome Cast Ball

Brand ZW

Product origin Shandong, China

Delivery time 7 days

Supply capacity 6000 tons per month

The surface hardness of the cast wear-resistant steel ball can reach 65HRC, and the hardness gradient distribution is average, with low wear, good toughness and less breakage. The product quality is not lower than the GB/T17445-2009 standard. It can improve the specific surface area of cement and the recovery rate of mine concentrate, improve the production capacity of the mill, extend the service life of the mill liner, and greatly reduce the production cost of the enterprise.

Download

Chromium content 4% - 6%, hardness HRC ≥ 47. This standard is called multi-element alloy ball, which has higher strength and wear resistance than low chromium steel ball

Material | 25mm-50mm HRC | 60mm-70mm HRC | 80mm-90mm HRC | |||

Surface | Core | Surface | Core | Surface | Core | |

Special Cr1:>20 | 60-64 | 59-63 | 60-64 | 58-62 | 60-64 | 57-61 |

Special Cr2:>15 | 58-62 | 57-61 | 58-62 | 56-60 | 58-62 | 50-59 |

High Cr:>10 | 58-62 | 57-61 | 58-62 | 56-60 | 58-62 | 50-59 |

Medium Cr:≥5 | 45-48 | 44-47 | 45-48 | 43-46 | 45-48 | 42-45 |

Low Cr:1-1.5 | 42-46 | 41-45 | 42-46 | 40-44 | 42-46 | 39-43 |

Raw material control of cast steel ball

1. Large channel steel, angle steel and scrap steel are selected as raw materials, and raw materials are strictly controlled;

2. Add high carbon ferrochrome, low carbon ferrochrome, ferromanganese alloy, copper, ferromolybdenum, ferronickel, ferrotitanium, rare earth and other alloys according to the needs of different products; The actual content of each alloy will be rechecked in our laboratory.

3. Different alloys and scrap steel shall be stacked in different areas and labeled

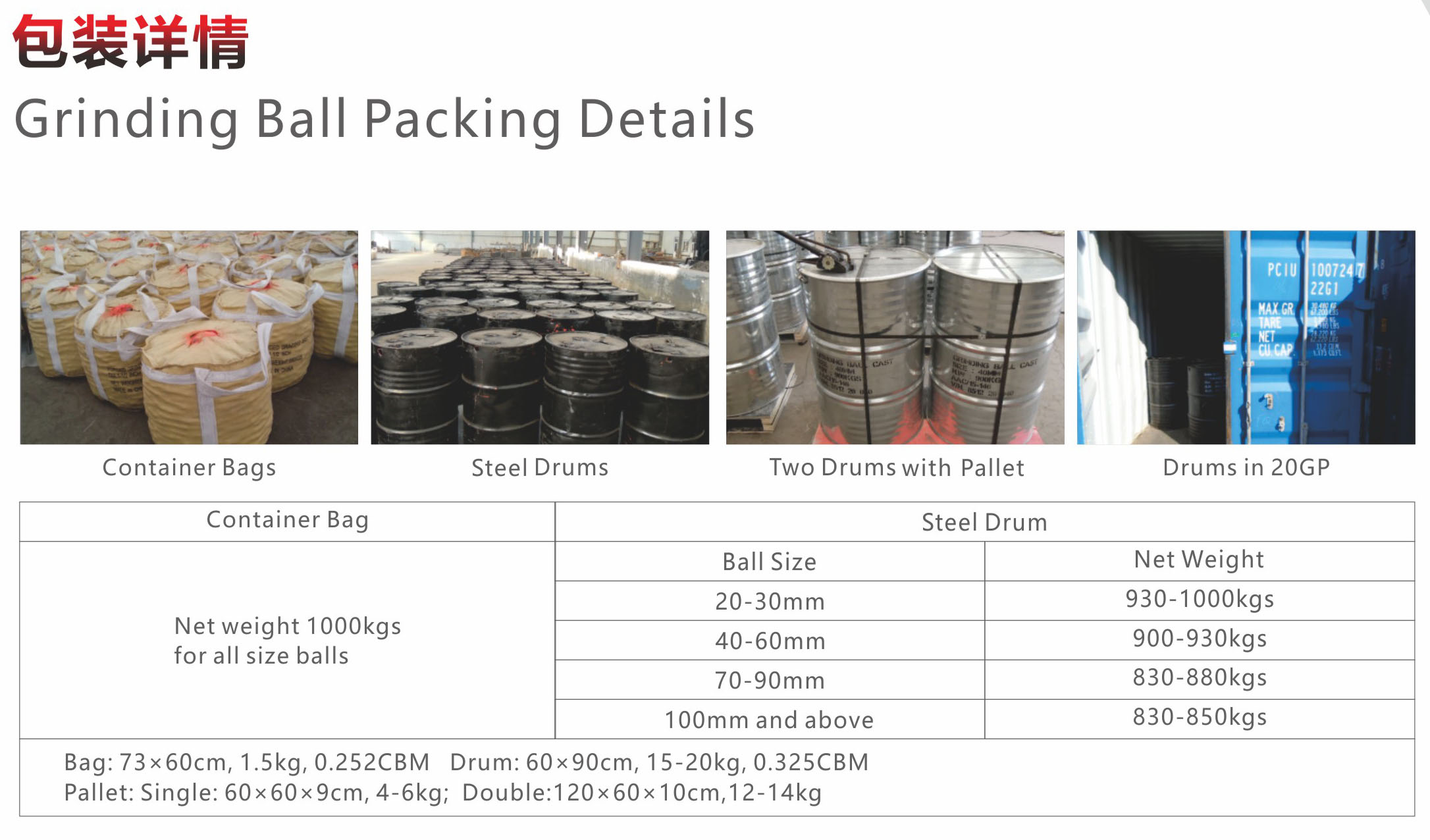

Packing

1000kgs in a bag or 850-900kgs in a steel drum, then 25 tons in a 20GP Container

QC&QI

1) Raw material: Size, Chemcial elements, Microstructure quality control (LAIWU STEEL)

2) Production Technical: Cutting Size, Heating Temperature, Quenching Technical, Tempering control.

3) Grinding Balls: Hardness, Size, Chemcial elements, Breakage Rate Checking

4) Thrid-Pary: SGS, BV ISO, TUV, COTECNA, AsiaInspection etc.

Company Profile

Jinan Zhongwei established in 2000 , we are a leading manufacturer and professional exporter grinding balls in China.

Our company covers an area of 15000 square meters, now we have 150 staff, including 13 technical staff. Annual output is 50000 tons to 80000 tons .

Main products : forged steel ball, cast iron ball ,grinding rod, cylpebs

We have exported to 20 more countries, UAE, Zambia,South Africa, Peru, Chile, Australia, UK, USA, Turkey and so on.